Some of these are as follows;

- During the years when the Turkish market was dominated by the turn only windows, Fıratpen released turn and tilt window systems which have greater insulation values but which were not preferred by the masses due to their high costs, and made these systems affordable for the final consumers. (Year 2000)

- In the period in which 60 mm profile width was dominant in the sector, Fıratpen released its 70mm profile system with 5 chambers which would increase the insulation and resistance values in high-rise buildings, blazed a trail in PVC window and door systems, raised the standard of the sector. (Year 2004)

- Fıratpen which initiated the procedures for CE markings, a legal obligation in Door and Window systems in Turkey and established the system by providing training at the points of sale with regard to CE marking, blazed another trail with this work for the purpose of increasing the quality in the sector. (Year 2007)

- In this period in which wooden pattern systems are used scarcely due to their high costs, Fıratpen made wooden pattern windows affordable for the final customers and lead the way for the sector which was having a hard time due to Asian Crisis. (Year 2009)

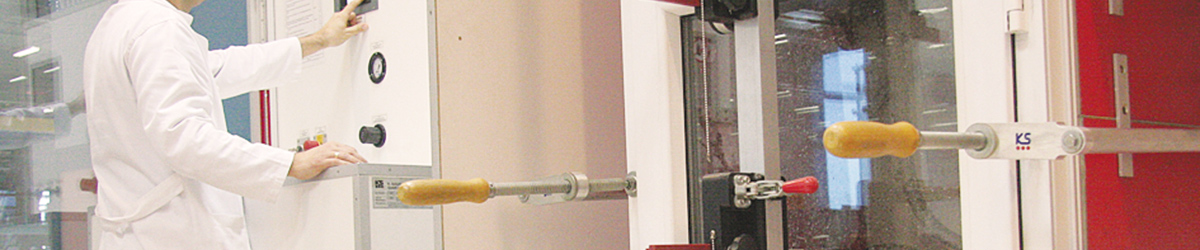

- Turkey is one of the leading countries in PVC profile manufacturing in Europe but until 2010 there hasn’t been any accredited laboratory in which "window tests" could be carried out in our country. Fıratpen blazed a trail with regard to this matter and introduced FUDEL, the first accredited window laboratory of Turkey to the sector. (Year 2010)

- Knowing that training is the most important shortfall of the sector, Fıratpen created the Certified Assembly Personnel standard, which was unavailable in our country, for the purpose of increasing the quality during the assembly stage, one of the most important points in PVC window systems and trained certified assembly personnel with regard to this matter; this standard has been approved by the Institute of Vocational Education and has been put into the service for the sector to utilise. This was a big step for the development of the sector. Fıratpen blazed a trail again and subjected the assembly personnel of the point of sales to test and awarded the successful personnel with Certificates with TÜRKAK accreditation. (Year 2014)

- In a time when the general standard of the sector was series of 70 and insulation values became more important, Fıratpen gave up 70 mm profile systems and preferred 75 mm Selenit Series with 6 chambers and again blazed the trail in the sector by increasing the standard to 75 mm. (Year 2015)

- Knowing that slide systems could be used within a limited geography and slide systems with high insulation could be bought with a high cost, Fıratpen designed the Zenia Slide which was a first in Turkey. With Zenia Slide insulation is achieved via the EPDM seals from all points when the window is closed and effects such as wind, noise and rain from outdoors are completely prevented to reach indoors. (Year 2015)

- Fıratpen R&D team which follows the home decoration products and colors which are trending in the world closely, meets different decorative expectations with 21 different colors by taking the laminate covered profiles out of the concept of wood. (Year 2015)

- In the environments and high-rise buildings exposed to high wind load, window series with high performance values should be preferred. Redonit reaches the maximum values in heating and sound insulation with 88 mm profile width, triple self-seal system design with 7 chambers, A Class wall thickness and triple glass applicability up to 44 mm. (Year 2016)

Fıratpen has always blazed the trail in the sector with its R&D works. With its technical staff, accumulated knowledge and market researches shaping the future, designed products are turned into prototypes and subjected to all tests stipulated by the European Standards in our laboratory, product development is carried out by subjecting them to tests and applications in the window production facility at our laboratory before being introduced to the market. The cooperation between our technical staff and our esteemed dealers during the design and R&D stage, the resulting product acquires top level success.